Modern washing machines are a blend of engineering precision and everyday practicality. Every component, no matter how small, has a specific purpose that contributes to performance, efficiency, and safety. Among these components, gaskets and seals play an essential but often overlooked role. They are the silent protectors of your washing machine—keeping water where it belongs, maintaining airtight pressure, and ensuring that every cycle runs smoothly without leaks or damage.

For most homeowners, these rubber or silicone rings may appear insignificant. Yet, without them, the washing process would quickly descend into chaos. A compromised gasket can lead to leaks, moisture buildup, and eventual corrosion. Seals, on the other hand, act as barriers that prevent water from escaping critical areas such as the drum, door, and motor. Together, they maintain the integrity of the entire washing system. Understanding their purpose, how they function, and how to maintain them is essential for keeping a washing machine in top condition.

How Gaskets and Seals Function

At the heart of every washing machine lies a high-speed, water-intensive operation. During each wash and spin cycle, the machine uses force, heat, and water pressure to clean clothes effectively. Gaskets and seals are strategically placed in areas where these elements intersect. Their function is to prevent water from leaking out while allowing the machine to operate safely.

In front-load washing machines, the most visible gasket is the large rubber ring around the door. This gasket ensures a watertight seal when the door closes, trapping water inside the drum during the cycle. The gasket’s flexible design allows it to compress and expand slightly as pressure builds, maintaining a tight barrier even under high rotation speeds.

Seals are often located deeper inside the machine—around the drum shaft, pump housing, and internal joints. These seals prevent water and detergent from seeping into the mechanical or electrical parts of the appliance. Without these seals, bearings would corrode quickly, motors would short-circuit, and the machine would fail prematurely. In short, gaskets and seals ensure that water remains in motion only where it is supposed to be.

The Science Behind Their Design

The design of washing machine gaskets and seals involves more than just fitting rubber into gaps. They are made from specialized materials such as synthetic rubber, silicone, or EPDM (Ethylene Propylene Diene Monomer) because these materials can endure repeated exposure to water, heat, and detergent chemicals. Each material must resist degradation while maintaining flexibility and airtight closure over years of use.

Temperature variation is a major challenge. Washing machines operate under both hot and cold cycles, which can cause expansion and contraction in the materials. High-quality seals are engineered to accommodate these shifts without cracking or losing elasticity. Similarly, the gasket around the door must be soft enough to compress yet strong enough to resist tearing when clothes brush against it or when the door is repeatedly closed.

Manufacturers also design gaskets with specific grooves and contours that guide excess water back into the drum instead of letting it leak. This precision design highlights how something as simple as a rubber ring is actually a product of sophisticated engineering.

Why Gaskets and Seals Fail Over Time

Despite their durability, gaskets and seals do not last forever. Over time, constant exposure to moisture, heat, and detergent residues takes a toll. Soap scum, lint, and dirt can accumulate around the gasket, trapping moisture that leads to mold and unpleasant odors. When this buildup hardens, it reduces the gasket’s ability to form a perfect seal.

Similarly, internal seals experience wear due to friction and vibration. Every spin cycle creates motion that stresses these components. If not maintained, small cracks or deformations can appear, allowing water to escape. These leaks often start small but can lead to major damage if ignored. Corrosion, electrical shorts, and even complete motor failure can occur if seals are compromised.

Frequent overloading of the washing machine also accelerates gasket and seal wear. When the drum is overloaded, pressure against the gasket increases, stretching it beyond its natural limit. This can cause warping or tears, leading to leaks around the door area.

The Hidden Role in Energy Efficiency

Beyond preventing leaks, gaskets and seals play a quiet but important role in energy efficiency. A properly sealed washing machine uses less water and detergent because it can maintain internal pressure more effectively. Leaks disrupt this balance, causing the machine to work harder to achieve the same results.

In addition, energy-efficient washing machines depend heavily on air and water-tight systems. For example, during high-speed spin cycles, the machine must maintain stability and pressure inside the drum. Even a small air leak can reduce efficiency and force the motor to use more power. Proper sealing ensures consistent performance and helps maintain low energy consumption over time.

The Impact of Poor Maintenance

Neglecting gaskets and seals can lead to a range of issues beyond visible leaks. One common problem is mold growth. The warm, damp environment inside a washing machine provides the perfect conditions for mold and mildew to thrive, especially around door gaskets. This not only causes unpleasant odors but also affects the cleanliness of clothes.

Another issue is vibration noise. When seals or gaskets become loose, the machine can vibrate excessively during spin cycles. These vibrations can damage internal components or even cause the washing machine to shift from its position. Such signs often indicate that the gaskets or seals need replacement or professional servicing.

In severe cases, neglected gaskets can allow water to seep into electrical panels, posing safety risks. It is far more cost-effective to maintain these parts regularly than to face expensive repairs later.

How Professional Technicians Handle Gasket and Seal Repairs

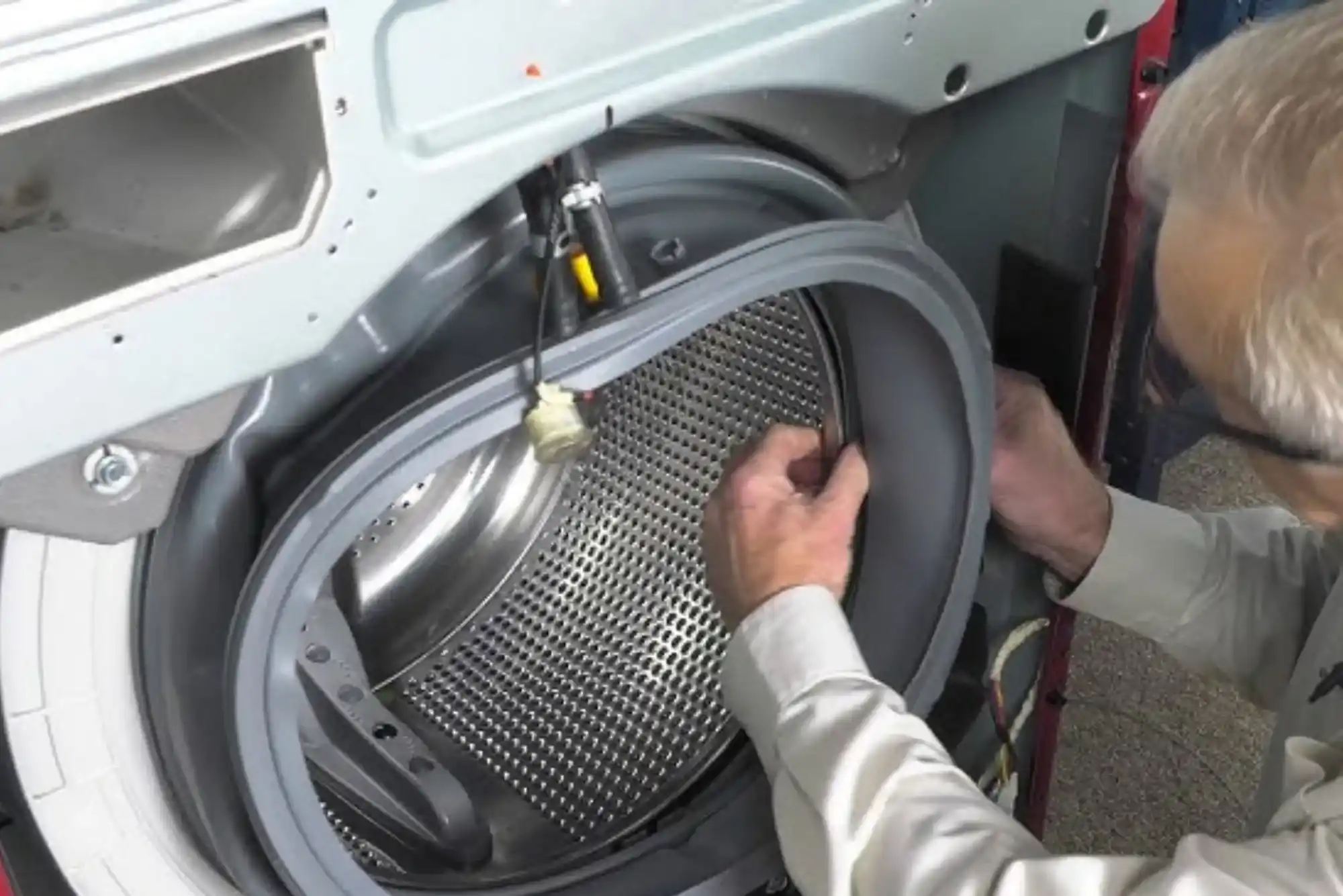

When gaskets or seals begin to fail, professional repair becomes necessary. A skilled technician will start by identifying the source of the problem—whether it’s a worn gasket, a broken seal, or corrosion in the surrounding components. The technician inspects the washing machine’s internal areas carefully to ensure no hidden damage exists.

Replacing a gasket requires precision. The old gasket must be completely removed, and the surface cleaned of residue to allow the new one to fit perfectly. Any misalignment can cause the new gasket to leak prematurely. Similarly, replacing internal seals requires disassembling parts of the drum or motor housing, which is why professional handling is recommended.

Modern repair services often use upgraded materials when replacing these components, ensuring longer life and better resistance to detergents and temperature fluctuations. By choosing professional washing machine repair rather than temporary DIY fixes, homeowners ensure the machine retains its efficiency and safety standards for years to come.

How Technology Is Improving Gasket and Seal Performance

Advancements in material science have significantly improved the quality of washing machine gaskets and seals. Manufacturers now use hybrid polymers that combine the flexibility of rubber with the resilience of synthetic compounds. Some modern gaskets feature antimicrobial coatings to prevent mold and bacterial growth, reducing maintenance needs.

Smart washing machines are also incorporating sensors that detect moisture or pressure loss caused by faulty seals. These sensors alert the user early, allowing preventive action before a leak becomes serious. This integration of technology demonstrates how even the simplest parts of a washing machine are evolving alongside digital innovation.

Engineers are also focusing on sustainability by developing recyclable gasket materials that maintain performance while reducing environmental impact. These innovations contribute to longer-lasting, eco-friendly appliances that align with global energy efficiency goals.

The Importance of Regular Inspection and Care

Routine inspection is key to prolonging the life of washing machine gaskets and seals. Cleaning the door gasket after every few washes helps prevent residue buildup. Leaving the door slightly open after a cycle allows air to circulate, preventing mold growth.

Even though these steps seem small, they significantly extend the gasket’s lifespan. For internal seals, regular professional maintenance ensures that the components remain tight and corrosion-free. Technicians can spot early warning signs such as water stains, rust, or reduced spin performance, preventing major breakdowns.

Periodic service appointments not only protect gaskets and seals but also improve the overall lifespan of the washing machine. A well-maintained appliance uses less energy, runs quieter, and operates more efficiently.

Future Trends in Washing Machine Sealing Systems

As washing machines become smarter and more advanced, the design of gaskets and seals continues to evolve. Manufacturers are exploring nanotechnology-based coatings that repel water and dirt more effectively. Some prototypes even feature self-healing materials that automatically close small cracks before leaks occur.

The goal of these innovations is not only to enhance performance but also to reduce the need for frequent repairs. Future washing machines may also include diagnostic software that evaluates gasket condition based on usage data, alerting users when replacement is due. This predictive maintenance will transform the way households care for their appliances, ensuring longer, trouble-free operation.

Small Components, Big Responsibility

Gaskets and seals might seem like minor parts of a washing machine, but their role is fundamental. They provide the invisible barrier that allows the machine to function safely, efficiently, and reliably. Without them, water leakage, energy waste, and equipment failure would become common occurrences.

Understanding their importance helps homeowners appreciate the engineering behind even the simplest appliance parts. Maintaining these components through regular cleaning and professional service ensures that the washing machine continues to operate at peak performance.

Ultimately, gaskets and seals symbolize how small innovations make a big difference in daily life. Their design reflects the delicate balance between technology, durability, and user convenience. As technology progresses, these components will continue to evolve—offering improved reliability, better hygiene, and greater energy efficiency for the modern home.